Set the quality standards which you want to achieve

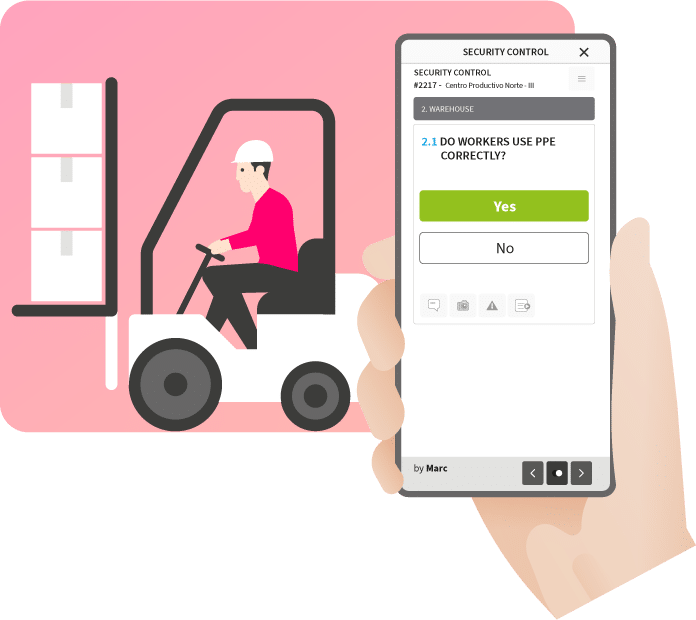

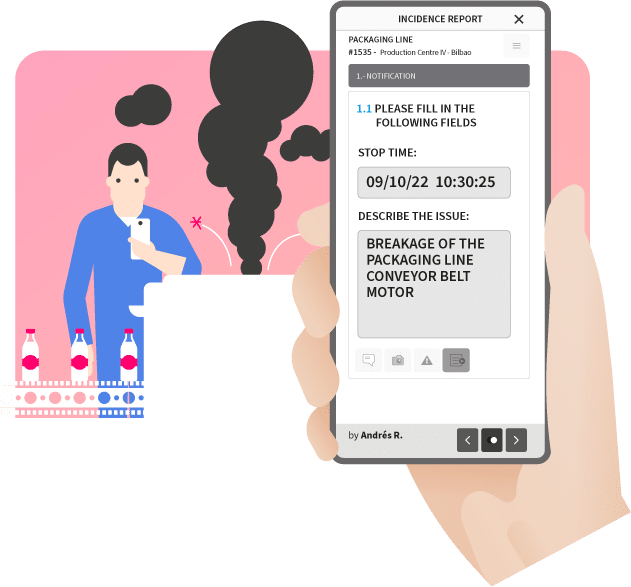

Setting standardized protocols, identifying areas of improvement, and guaranteeing your standards are being met has never been this simple. With Iristrace you have an agile tool for your lean operations making it effortless to become ISO 9001 certified.

Digitalize your gemba walk and provide yourself with comprehensive integrated LPA data using the information collected and presented from the checklists on your own dashboard. Ensure that all staff maintain the 5s methodology on each step along the way, not just to minimize waste, but also to provide the highest degree of quality achievable to your customers.