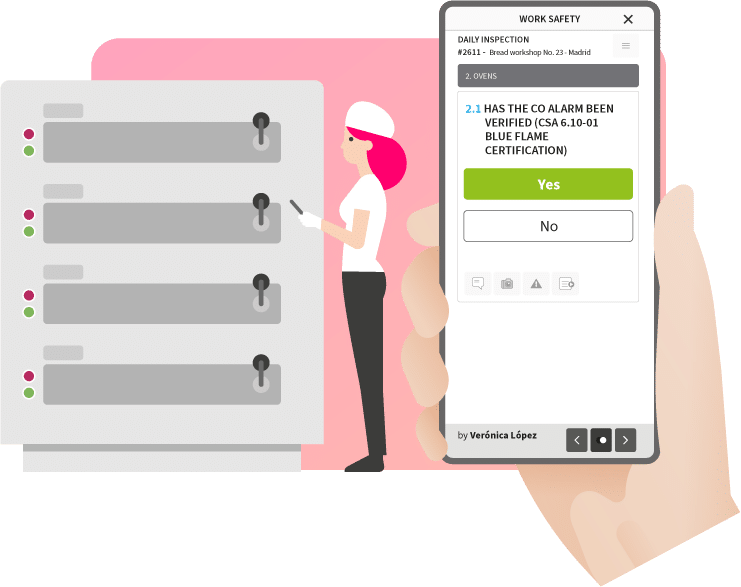

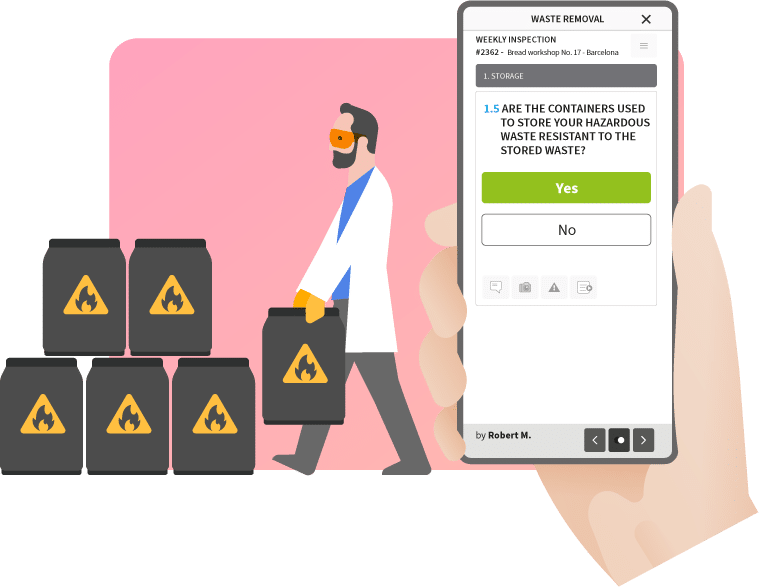

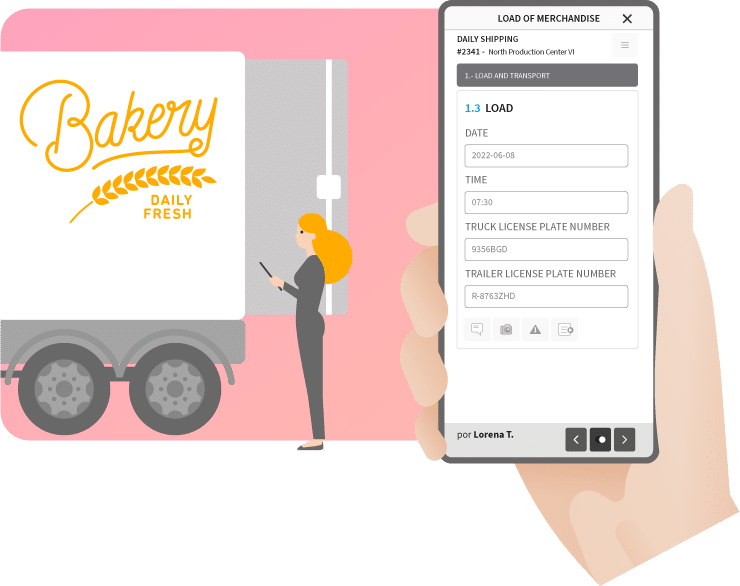

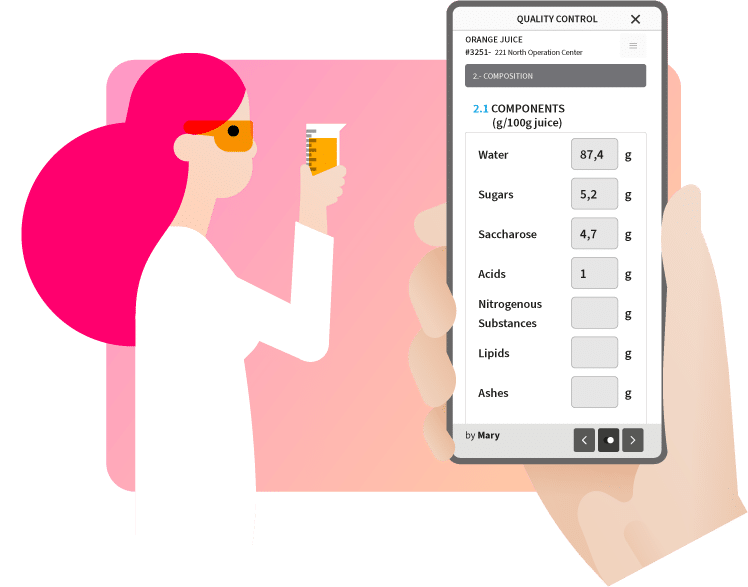

Capture data easily with the mobile app

Keep all your processes under control by capturing data from your mobile device. With Iristrace you can create checklists to ensure your processes are compliant.

- Add images and comments

- Identify incidents and get them resolved through dedicated action plans

- Generate reports with just one click and receive notifications about important issues