Valentine’s Day is here. This means hearts are melting, but also tons of chocolate. Just as millions of couples share their love by giving each other a box of chocolates, many confectioners demonstrate their passion for the art of designing and making chocolates with admirable dedication every day. From choosing the highest quality ingredients to melting the cacao butter and molding the chocolates, through the creativity in designing the tastiest recipe, as well as the most original shape and decoration, these professionals work full stretch to steal our hearts with their delicious creations.

To delight us during such a sweet moment, it is a top concern for them to avoid failures in any of the processes that could cause a batch to spoil. Of course, this is no easy task, as every process involves precision and creativity to ensure the quality and visual appeal of the chocolates. The cacao butter must be melted at the correct temperature, the exact amount must be measured when adding each ingredient… All this while ensuring the personnel’s health and safety through a strict control of occupational hazards applied at each stage of the production. Equally important is to guarantee food safety, avoiding contamination of ingredients by external agents or cross-contamination due, for example, to the presence of residues during the filling stage of ingredients that are potential allergens for some consumers. There are many details that must be verified during the production process.

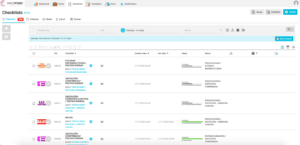

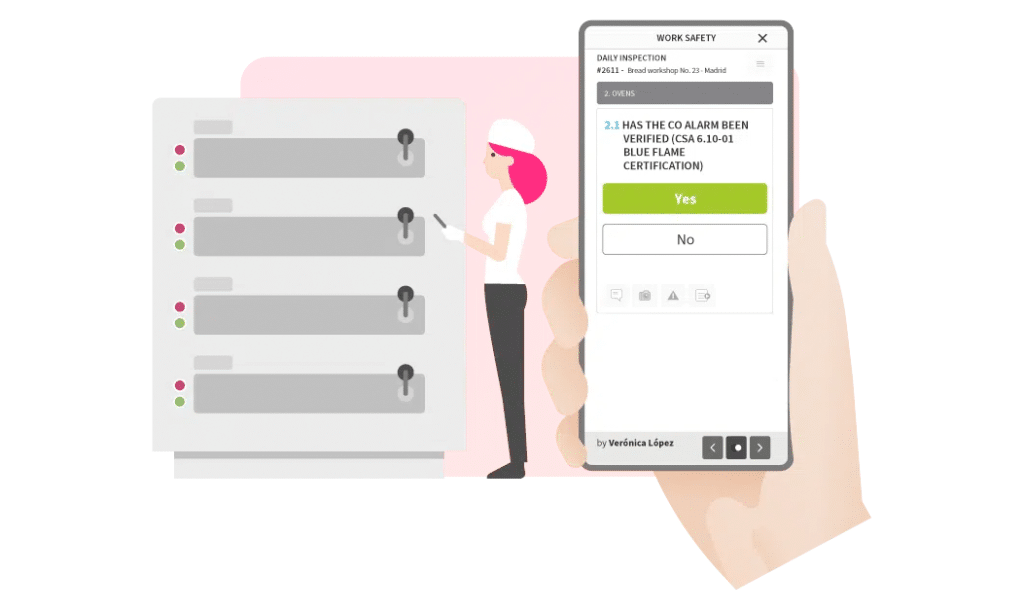

To simplify these verification steps and avoid risks, we offer a tool to digitalize processes through forms, checklists, work orders and visual work instructions. Our mobile application facilitates data collection in real time and from anywhere in the factory, during transportation, or in the stores. Popular processes in the chocolate industry, such as scheduling and tracking preventive maintenance tasks of the tempering machine or cleaning all parts of this machine when changing ingredients handled with the same machine (e.g. from milk chocolate to white chocolate), get documented faster with Iristrace, keeping an easily traceable digital record of each operator activity.

Leading companies in the food industry already rely on it to record key parameters such as temperatures, cooking times and quantities. They also document safety checks and inspections and monitor critical control points. With the tool, they get instant visibility on verifications taking place not only in the factory, but also during distribution, or in the stores. Are all outlets ready and have they received the desired quantity? How did the marketing campaign work for them? It is an effortless way to save paper and time and avoid spreadsheet versioning confusion in the collection of any type of data. This way love will still be in the air, but not your time, because you will have peace of mind that operations, safety, and quality are under control.

If you want to know more about the digitization of your processes, visit our website, where you can receive personalized assistance from our success consultants.